Dubi Chem is one of the METAL RUST BRIGHT manufacturers, exporters, and suppliers in Fujairah, Sharjah, Abu Dhabi, Ajman,Ras Al Khaimah, kuwait, Muscat, Dubai UAE. We are supplied to various industrial markets including Household, Institutional Cleaning, Personal Care, and Industrial sectors including Oil fields, chemical, Animal feed additive, Food additive, Agrochemical, Fertilizer, pharmaceuticals, water treatment, Minerals, Lubricants, Marine Industry, Metal Working chemical industry, and Coatings markets.

RXSOL-16-1011-025 (Metal Brite) or METAL RUST BRIGHT

Rust cleaner Superior formulaheavy duty and highly Concentrated liquid blend of surfactant & organic compound containing rust penetrating agent, solubilizer and inhibited phosphoric acid.

Product Description:

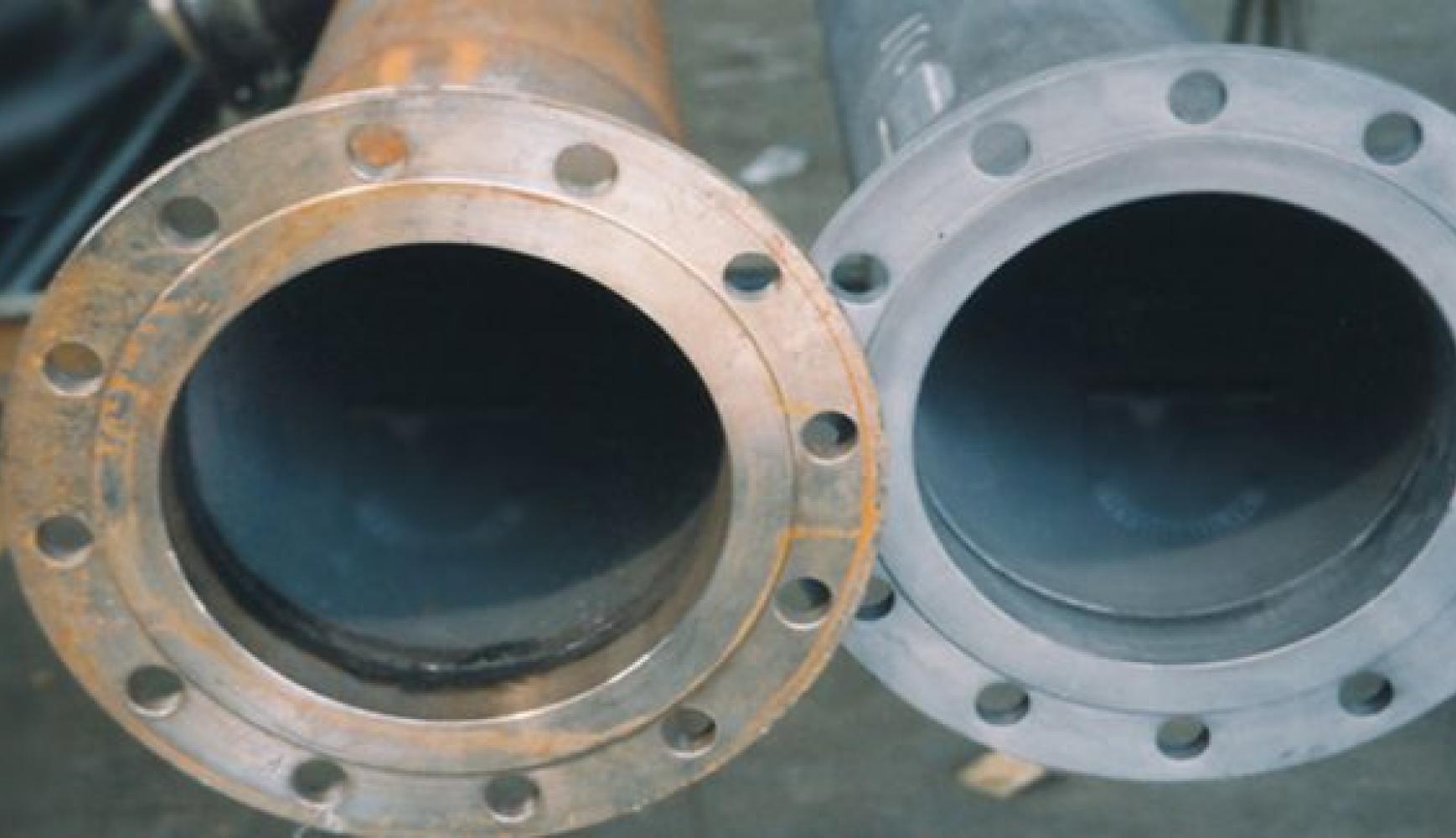

Metal Rust Bright MRB is heavy duty and highly Concentrated liquid blend of surfactant & organic compound containing rust penetrating agent, solubilizer and inhibited phosphoric acid. Metal Rust Bright MRB is a useful product in maintenance and cleaning sector. In the marine shipping industry, Metal Rust Bright MRB is used as a rust remover. Largest seller and supplier of Metal Rust Bright MRB in INDIA and Middle East.

Product Application:

For polishing almost all metals, such as brass, copper, nickel, chrome, stainless steel, aluminium and even for machinery and golf clubs.

MARINE - Rust Stain cleaner Metal Rust Bright

RXSOL-16-1011-025 ( Metals Rust Clean Bright ) can be used as a spot cleaner after cleaning fats and fatty acids , can be used on painted surface

A superior heavy duty and highly Concentrated liquid blend of surfactant & organic compound containing rust penetrating agent, solubilizer and inhibited phosphoric acid with ionic and non ionic emulsifier.

For polishing almost all metals, such as brass, copper, nickel, chrome, stainless steel, aluminium and even for machinery and golf clubs.

Product Dose:

Field:- specially designed for removal of rust from any steel surface area and rust stain from Brass , Copper, S.S wood, ceramic and aluminium surfaces, painted or not . And act as surface brightner.

Procedure for Use:-RXSOL-16-1011-020 is highly concentrate

Dilute in water (always use plastic jar and RXSOL-16-1011-020 should be added to water never add water to RXSOL-16-1011-020.)

Surface should be sound clean and free from oil, grease, dirt etc.

Diluted materials apply on rusted area for 15 to 20 minutes then wash off with water repeat if necessary. (For stubborn rusted stains.)

Note:- For steel surfaces; remove oil, grease and old paint. Wet down entire surface with neat Metal Bright- Rx and allow to dry. Second wash may be necessary. Surface should have a grey/white appearance when the Metal Bright- Rx is dry. Steel surfaces will have a resistance to rust and will render a good base for paint. For removal of rust stains on painted surfaces and wood, Metal Bright Rx should be applied at full concentration for heavy stains, or diluted to 20-50% for light stains. Allow to soak for 15 to 30 minutes and wash off with water. A second application may be necessary to remove the stubborn stains.

Spraying Direction: – Using an empty / clean 210 liter drum, fill with 190 liter of fresh water and add 20 liters of Metal Rust Bright This makes a 10% solution, which can be sprayed onto areas in coated tanks where rust stains are showing and over actual rusted areas. Once spraying is completed, wait 20-30 minutes and fresh water rinse with lots of water, if possible use butterworth machines for a more efficient result. This method can be used in stainless tanks to “freshen up” the look of the stainless materials. Make sure to rinse the tank very well, as residual detergent within the Metal Rust Bright will show up in a Wall Wash.

Injection– Not suitable.

Re-circulation: – When hand spraying is inadequate (too much area to cover), prepare a 2% - 5% solution in the tank using fresh water, heat solution to 50o C, then circulate the solution through Butterworth machines for 3 x 45 minutes drops minimum. When using fixed machine recirculate for a minimum of 3 cycles. Rinse out the tank using hot seawater 85o C for 2 hours making sure that there is no form remaining in the water at the pumpstack drain cock. After the hot wash, the tank must be rinsed with fresh water and dried.

* If the mixture is allowed to overheat, it will soften epoxy / phenolic coating. *

Use a strainer at the pumpstack when circulating any solution. Tank Lining – Stainless / Epoxy, Phenolic

Product Note:

Characteristics:-

• Non-flammable.

• Prevents further rusting.

• Economical, cost effective.

• Surface brightening

• Protects and maintains from corrosion

• Acts as rust proofing agent before the application of paints or coatings.

• It doesn’t affect rubber and plastic compounds

Note:- When cleaning aluminium, brass & copper flush with water upon completion of cleaning.

We are trying our best to supply every chemical you may wish to buy. However, if there is something you can’t find, feel free to contact us and we will find just what you are looking for and offer you a competitive price. We have many customers in the United States, Canada, Mexico, Australia, United Kingdom, and European Union countries and retain long-term cooperation. For more information or to request a particular product, call customer services or Given website Email address.